Call Us

86-755-82924037

Call Us

86-755-82924037

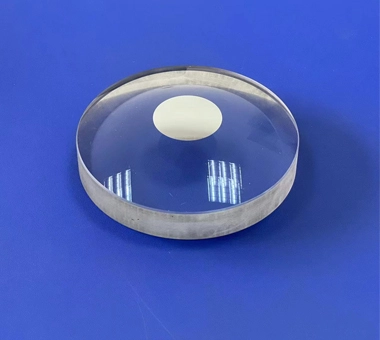

Zinc selenide/zinc sulfide windows are processed through fine grinding, grinding, measuring, ultra-high precision polishing and other processes. Under precise control of the machine tool and processing environment, ultra-high precision correction polishing technology is used to polish the window surface. , achieving an infrared window with an optical plane surface shape accuracy of ≤0.1 micron and a surface roughness Ra of ≤0.01 micron.

| Zinc selenide zinc sulfide window product parameter table | |||

| project | Indicator requirements | ||

| 1.Material | Zinc selenide, zinc sulfide infrared materials | ||

| 2. Diameter | OD≤300mm OD±0.025 or according to customer requirements | ||

| 3. Center thickness | T=0.1~50mm±0.01 or according to customer requirements | ||

| 4. Effective focal length | according to customers needs | ||

| 5. Working distance | according to customers needs | ||

| 6. Effective aperture | ED>80% aspheric area | ||

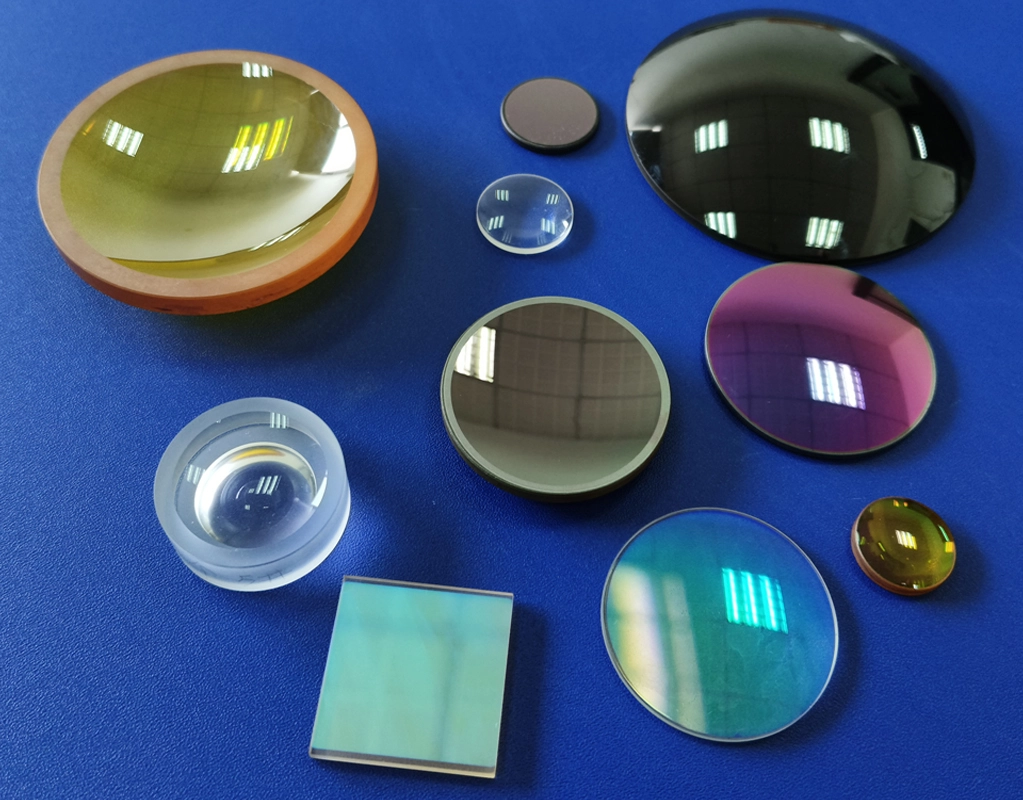

| 7.Coating | AR or DLC coating R<0.5% @λnm | ||

| 8. Surface shape | Ultra-high precision Rt≤0.1μm, high precision Rt≤0.5μm, precision Rt≤1μm | ||

| 9.Surface quality | 60-40, 40-20, 20-10, 10-5 | ||

One-stop customized production: Solar Valley processes various custom optical windows, circular, D-shaped, square, trapezoidal and other structural infrared windows according to customer requirements. It can provide windows in different size ranges and materials. The base material is selenium. Zinc sulfide (ZnSe), zinc sulfide crystal materials, and provide various optical coatings such as anti-reflective coating, high-reflective coating, spectroscopic film, metal film, etc.

Material: Zinc selenide (ZnSe) and zinc sulfide crystal materials are commonly used materials for producing efficient infrared windows in imaging systems.

Infrared window properties: strong resistance to mechanical impact and thermal shock, high surface hardness, good transmittance in the infrared field, and suitable for use in harsh environments. It can be made very thin and is suitable for visible light and mid- and far-infrared spectrum. It is usually used as a protective window for electronic sensors or detectors of the external environment. It is used to separate the environment on both sides and isolate the inside and outside of the instrument from each other. This protects internal components.

Product indicator description:

1. Maximum dimensions of circular zinc selenide and zinc sulfide windows: OD≤φ300mm, thickness 0.1~50mm

2. Maximum dimensions of square zinc selenide and zinc sulfide windows: L×W ≤300×300mm

3. Zinc selenide and zinc sulfide windows can reach the following accuracy levels according to customer requirements:

Ultra-high precision grade: surface error <0.1μm, surface roughness <0.01μm

High precision grade: Surface error <0.5μm, surface roughness <0.05μm Precision grade: Surface error <1μm, surface roughness <0.1μm

Surface defect grade: 60-40, 40-20, 20-10, 10-5. Produced according to customer requirements.

Coating: Coating according to customer requirements.