Call Us

86-755-82924037

Call Us

86-755-82924037

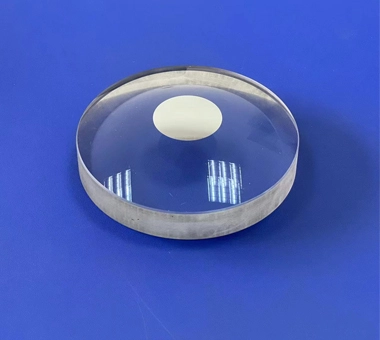

Zinc sulfide lens uses a single point diamond ultra-precision multi-axis free-form surface processing machine, through ultra-precision single point turning, grinding, measurement, ultra-precision polishing and other processes, under the condition of precise control of the machine tool and processing environment, achieving ultra-precision machining of the optical aspherical plastic domain. The use of ultra-precision correction polishing technology to polish the lens surface, achieving the optical aspherical surface accuracy≤0.1 micron, surface roughness Ra≤0.01 micron infrared aspherical lens.

| ZnS Zinc Sulfide Lenses product parameter table | |||

| Project | Indicator requirements | ||

| 1. Material | Zinc sulfide materials | ||

| 2. Diameter | OD≤150mm OD±0.025 or according to customer requirements | ||

| 3. Center thickness | T±0.01 or according to customer requirements | ||

| 4. Effective focal length | according to customers needs | ||

| 5. Working distance | according to customers needs | ||

| 6. Effective aperture | ED>80% aspheric area | ||

| 7. Coating | AR or Reflection or Metal coating R<0.5% @λnm | ||

| 8. Surface shape | Ultra-high precision Rt≤0.1μm, high precision Rt≤0.5μm, precision Rt≤1μm | ||

| 9.Surface quality | 60-40, 40-20, 20-10 | ||

One-stop customized production: Solar Valley can process a variety of infrared lenses, flat convex, double convex, convex and concave structure aspherical zinc sulfide lens according to customer requirements.The shape of zinc sulfide lens can be round, D-type, square and so on.

Material: Zinc sulfide has the characteristics of high purity, insoluble in water, moderate density, easy processing, etc., with good refractive index uniformity and consistency, high transmittance in the middle infrared band, with the shortening of wavelength, absorption and scattering enhancement.

Lens performance: Zinc sulfide (ZnS) is widely used in optical components of thermal imaging systems for infrared Windows and thermal bands (8 to 14μm), and its relatively high transmittance through 3-5μm and 8-10μm makes ZnS ideal for multispectral applications, widely used in the manufacture of infrared optical components such as infrared Windows, fairings and lenses.

Product indicators:

1. Maximum external dimension of circular zinc sulfide lens: OD≤φ150mm

2. Maximum external dimension of square zinc sulfide lens: L×W ≤100×100mm

3. Zinc sulfide lens can reach the following accuracy levels according to customer requirements:

Ultra-high precision: surface shape error < 0.1μm, surface roughness < 0.01μm

High precision grade: Surface error < 0.5μm, surface roughness < 0.05μm Precision grade: Surface error < 1μm, surface roughness < 0.1μm

Similar product of GaAs focus lens is also provided for you to explore.

Surface defect grade: 60-40, 40-20, 20-10 according to customer requirements.

Coating: According to customer requirements for coating, can provide no coating or a variety of broadband anti-reflection coating options.