Call Us

86-755-82924037

Call Us

86-755-82924037

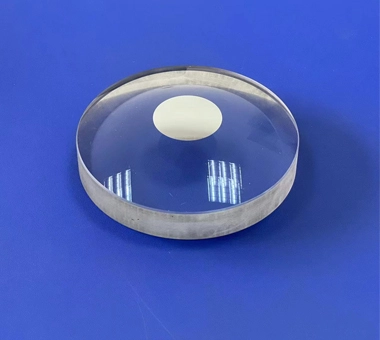

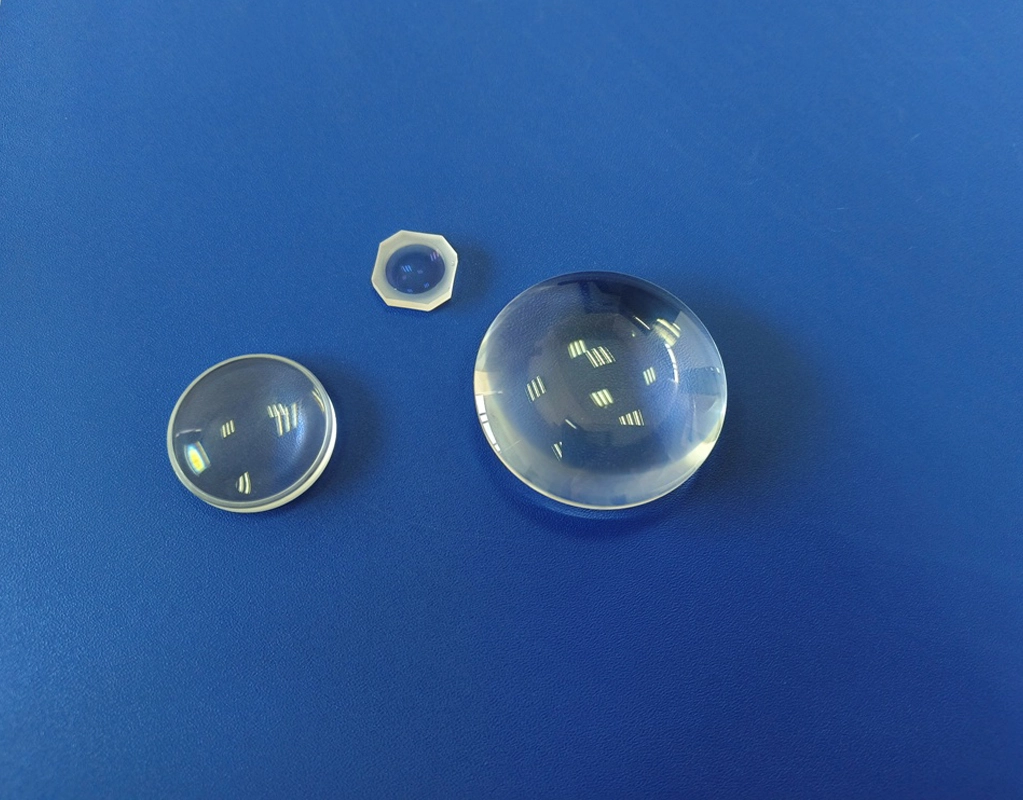

Sapphire lenses are manufactured with unparalleled precision through the use of advanced multi-axis free-form surface machining technology. The production process encompasses ultra-precision fine cutting, detailed grinding, exact measurement, and meticulous polishing. Each step is meticulously managed, ensuring the machinery and the environment are precisely controlled to achieve the highest standards of optical surface machining. The application of sophisticated correction polishing technology further refines the lens surface. As a result, these sapphire lenses achieve an exceptional level of optical aspherical surface shape accuracy of ≤0.1 micron and a surface roughness of Ra≤0.01 micron, making them ideal for applications requiring the utmost in optical clarity and durability.

| Sapphire Lenses product parameter table | |||

| Project | Indicator requirements | ||

| 1.Material | Sapphire materials | ||

| 2. Diameter | OD≤300mm OD±0.025 or according to customer requirements | ||

| 3. Center thickness | T±0.01 or according to customer requirements | ||

| 4. Effective focal length | according to customers needs | ||

| 5. Working distance | according to customers needs | ||

| 6. Effective aperture | ED>80% aspheric area | ||

| 7.Coating | AR coating R<0.5% @λnm | ||

| 8. Surface shape | Ultra-high precision Rt≤0.1μm, high precision Rt≤0.5μm, precision Rt≤1μm | ||

| 9.Surface quality | 60-40, 40-20, 20-10 | ||

One-stop customized production: Solar Valley can process a variety of infrared lenses, flat convex, double convex, convex concave structure sapphire lens according to customer requirements.Also provide a variety of sapphire optical components, such as aspherical sapphire lens, sapphire window, sapphire mirror, sapphire cylindrical mirror and so on.

Material: Sapphire is excellent in optical and physical properties, with high surface hardness, mechanical wear resistance, high damage threshold and long service life. It does not react chemically with most common acids and bases even at temperatures of 1000°C and has a melting point of more than 2000°C, making it ideal for high temperature applications.

Lens performance: The range of sapphire lens transmittance covers the ultraviolet band to the mid-infrared band and the entire wavelength range, has a high transmittance, sapphire lens can be used in imaging systems, spectroscopy, military optical sensors, endoscopes, vacuum Windows and so on.

Product indicators:

1. The maximum dimension of round sapphire lens: OD≤φ300mm

2. Maximum outline size of square sapphire lens: L×W ≤200×200mm

3. Sapphire lens can reach the following accuracy levels according to customer requirements:

Ultra-high precision: surface shape error < 0.1μm, surface roughness < 0.01μm

High precision grade: Surface error < 0.5μm, surface roughness < 0.05μm Precision grade: Surface error < 1μm, surface roughness < 0.1μm

Similar product of GaAs focus lens is also provided for you to explore.

Surface defect grade: 60-40, 40-20, 20-10 according to customer requirements.

Coating: According to customer requirements for coating, can provide no coating or a variety of broadband coating options.