Call Us

86-755-82924037

Call Us

86-755-82924037

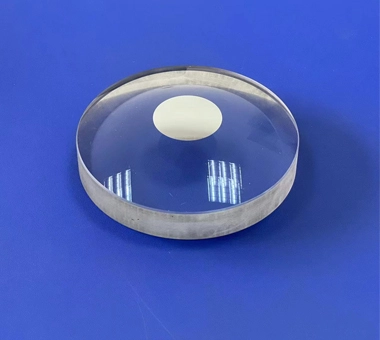

ROSA Optical Subassembly (Receiver Optical Subassembly), mainly composed of detectors and adapters, in high data rate optical fiber modules, usually PIN or ADP photodiode and TIA assembled in a sealed metal housing, The optical receiving component is mainly used to convert optical signals to electrical signals (O/E conversion), where the ROSA lens component usually encapsulates a microlens in a coaxial metal shell. Microlens using high temperature molding, the advantages of the receiver optical subassembly are low production cost, high precision, suitable for aspherical microlens mass production. ROSA lens assembly is one of the core components of a variety of optical systems, mainly used to convert optical signals into electrical signals (O/E conversion).

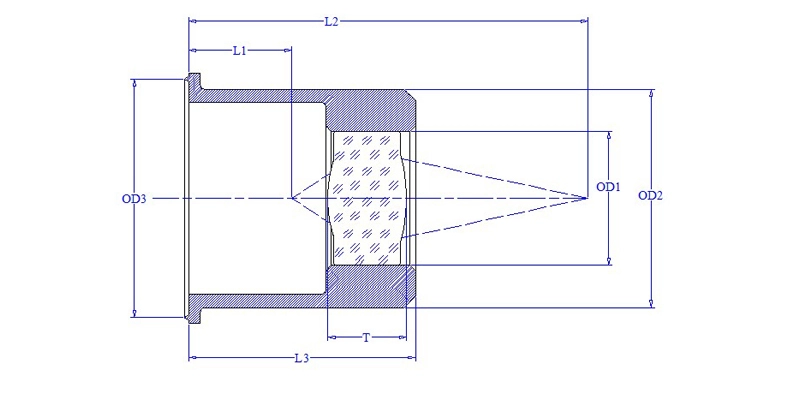

| ROSA lens assembly parameter table | |||

| project | Indicator requirements | ||

| 1. Material | Use various high and low refractive index optical glass and stainless steel, SF20F and other metal housings | ||

| 2. Outer diameter | Round OD≤20mm | ||

| 3. Thickness | according to customers needs | ||

| 4. Effective focal length | according to customers needs | ||

| 5. Working distance | according to customers needs | ||

| 6. Design wavelength | according to customers needs | ||

| 8. Coating | AR anti-reflection coating R<0.5% @λnm according to customer requirements | ||

| 9. Eccentricity | according to customers needs | ||

| 10. Effective aperture | ED>90% aspheric area | ||

| 11. Surface shape | Ultra-high precision Rt≤0.1μm, high precision Rt≤0.5μm, precision Rt≤1μm | ||

| 12. Surface quality | 60-40, 40-20, 20-10, 10-5 | ||

One-stop customized production: Solar Valley processes TO CAN laser diode of various sizes and structures according to customer requirements, and the optical surface of the lens can be spherical and aspherical.

Material: Use a variety of high and low refractive index optical glass and metal material coaxial shell

ROSA lens component performance: Solar Valley strictly matches the diameter and center thickness of ROSA lens components to ensure package quality and high precision required center thickness. Tianggu uses various packaging technologies such as UV curing, gluing, high-temperature powder curing and so on in different glass and metal coaxial housings to precisely control the focal length and various optical properties of ROSA lens components.

Product size indicator description:

Maximum dimension of ROSA lens assembly: OD≤φ20mm

ROSA lens assemblies can achieve the following accuracy levels according to customer requirements:

Ultra-high precision: surface shape error < 0.1μm, surface roughness < 0.01μm

High precision grade: Surface error < 0.5μm, surface roughness < 0.05μm Precision grade: Surface error < 1μm, surface roughness < 0.1μm

Surface defect grade: 60-40, 40-20, 20-10, 10-5 According to customer requirements.

Coating: Coating according to customer requirements.