Call Us

86-755-82924037

Call Us

86-755-82924037

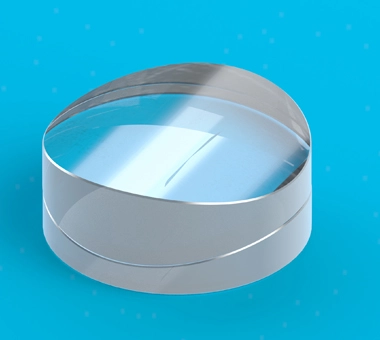

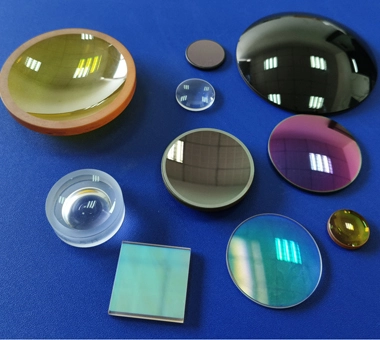

Quartz Substrates - A1 are foundational elements in the realm of optical communication devices, distinguished by their compatibility with the thermal expansion coefficient of optical fibers. These substrates boast high dimensional accuracy, remarkable hardness, and superior environmental resilience, making them indispensable in the construction of optical couplers, ribbon fiber welding protectors, and high-power laser systems. Fabricated from preformed quartz rods, the manufacturing process involves meticulous cleaning, securing atop a high-temperature graphite furnace, and exposure to a core protected by inert gas. Through continuous traction, drawing, and cutting techniques, A1 quartz substrates are produced on a large scale. They feature transparent surfaces, exceptional performance, and high dimensional precision, thereby enhancing component quality while minimizing costs.

| A1 Quartz Substrate Specification Sheet | |||

| Item | Specification | ||

| Material Properties | Quartz: Purity of SiO2>99.9% | ||

| Density: 2.2×103Kg/m3 CTE: 5.5×10-7cm/cm℃ | |||

| Compressive Strength: 4.8×107Pa (N/m2) (7000psi) | |||

| Tensile Strength: >1.1×109Pa (160000psi) | |||

| Softening Point: 1683℃ Annealing Point: 1215℃ Deformation Point: 1120℃ | |||

| Refractive Index: 1.4585 | |||

| Dielectric Constant: 3.75 (@1MHz) Insulation Strength: 5×107V/m | |||

| Dimensions and Tolerances | OD: φ0.5≤OD≤φ5mm | ||

| Width: W±0.1mm according to customer requirements. | |||

| Height: H±0.05mm according to customer requirements. | |||

| Arc Angle R: High temperature drawing process rounded angle, R < 0.1mm. | |||

| Length: L=0.5~100mm±0.2mm, or according to customer requirements. | |||

| Surface Quality | The product has no cracks, the two ends are grinding surfaces, and the cylindrical and flat surfaces are transparent surfaces. | ||

Material: high purity fused quartz, purity of SiO2> 99.9%, softening point > 1650℃, high strength, high wear resistance, high transmittance.

Properties: The quartz substrate is made of high-temperature melting and wire-drawing, the surface is transparent, and the surface micro-cracks and local surface recessive cracks of the optical fiber positioning slot are eliminated. The quartz substrate has high strength, and it is not easy to crack and break when the optical fiber is fixed by dispensing, and the dispensing pass rate is high.

Environmental performance: The hydraulic and electrical composite wire drawing production process does not use any chemical solvents, and the material and production process does not contain or involve the hazardous substances that forbidden in EU RoHS directive and Reach regulation.

Quality stability: Through CNC host, feeding mechanism, traction mechanism, laser rangefinder closed-loop control, can achieve accurate drawing of the required diameter and slot width of the quartz substrate, with high precision consistency, accurate optical fiber positioning slot shape, and excellent production stability.