Call Us

86-755-82924037

Call Us

86-755-82924037

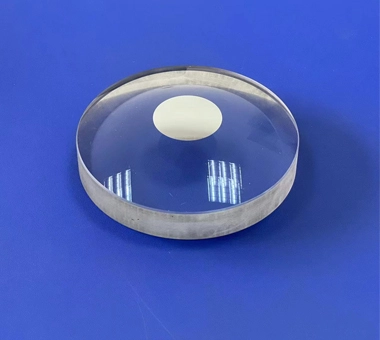

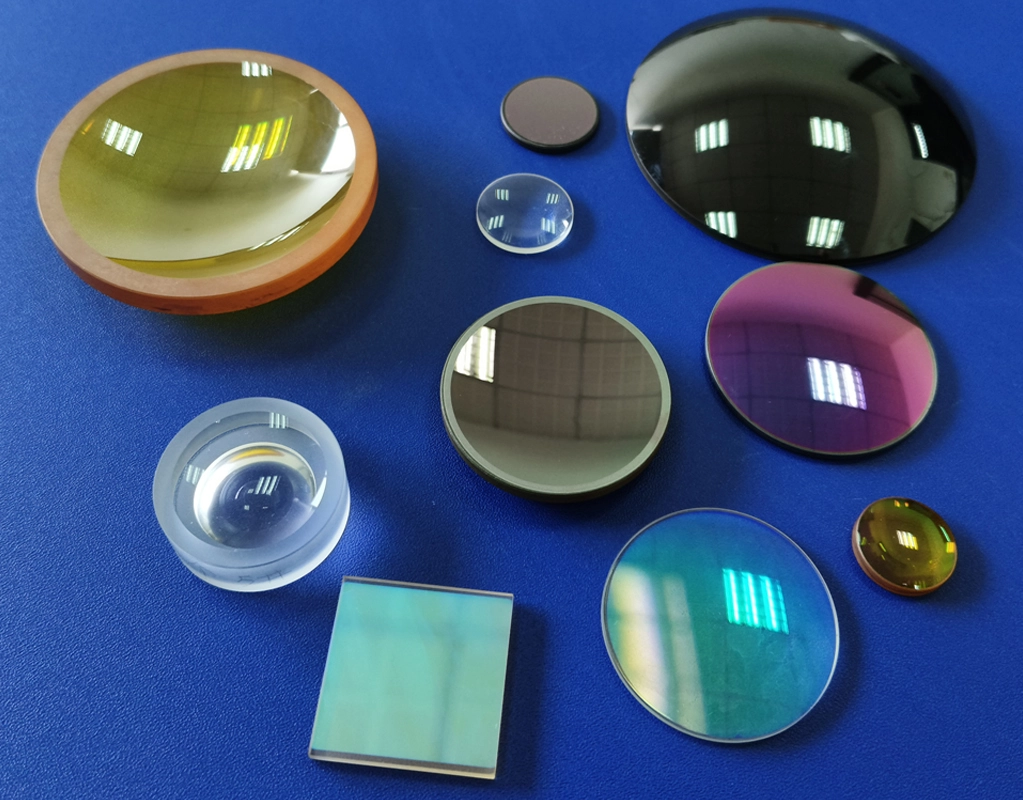

Molded Infrared Aspheres are crafted through a highly specialized process that utilizes ultra-high-precision molds. These molds are employed under the safeguard of inert gas atmospheres, with specific high temperatures and pressures applied to create infrared aspherical lenses. This method ensures that the lenses achieve exceptional contour accuracy and superior surface quality. One of the key benefits of Molded Infrared Aspheres is their cost-effectiveness, providing a low-cost solution without compromising on precision. Additionally, the process is well-suited for high-volume production, making these lenses an ideal choice for applications requiring both high precision and affordability in significant quantities.

| Molded infrared aspheric lens product parameter table | |||

| project | Indicator requirements | ||

| 1. Material | Various infrared materials. | ||

| 2. Diameter | OD±0.025 or as per customer requirements | ||

| 3. Center thickness | T±0.01 or according to customer requirements | ||

| 4. Effective focal length | according to customers needs | ||

| 5. Working distance | according to customers needs | ||

| 6. Effective aperture | ED>80% aspheric area | ||

| 7. Coating | R<0.5%@λnm | ||

| 8. Surface shape | Ultra-high precision Rt≤0.1μm, high precision Rt≤0.5μm, precision Rt≤1μm | ||

| 9. Surface quality | 60-40, 40-20, 20-10 | ||

One-stop design and customized production: Solar Valley designs and high-temperature molding processes various plano-convex, biconvex, and convex-concave structure aspheric infrared lenses according to customer requirements.

Material: Tianyanggu Company's molded infrared lens materials are selected according to customer requirements, including molded infrared materials produced in Japan, China, and the United States.

Mold: Tianyanggu Company produces ultra-high-precision aspherical compression molding molds with various structures according to customer requirements. The materials include tungsten carbide, ceramics, etc.

Lens properties: uniform light spot, clear projection, complete specifications, aerospace quality, used in night vision goggles, medical endoscopes, laser processing, infrared thermal imaging cameras, temperature recorders, infrared fundus cameras, satellite infrared telescopes, etc. .

Product indicator description:

1. Maximum dimensions of circular aspherical molded infrared lens:

Lens diameter: ≤φ30mm

2. Maximum dimensions of square aspherical infrared molded lens: Lens dimensions: ≤25×25mm

3. Aspherical molded lenses can reach the following accuracy levels according to customer requirements:

Ultra-high precision grade: surface error <0.1μm, surface roughness <0.01μm

High precision grade: Surface error <0.5μm, surface roughness <0.05μm

Precision grade: Surface error <1μm, surface roughness <0.1μm

Surface defect grade: 60-40, 40-20, 20-10, produced according to customer requirements.

Coating: Coating according to customer requirements.