Call Us

86-755-82924037

Call Us

86-755-82924037

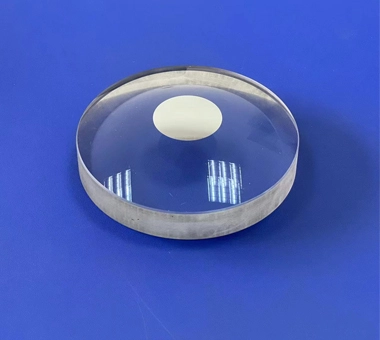

Germanium lenses are crafted with exceptional precision using a single-point diamond ultra-precision multi-axis free-form surface machining tool. This sophisticated process includes ultra-high-precision single-point turning, meticulous grinding, accurate measuring, and advanced polishing techniques. Every step is conducted under stringent control over both the machinery and the environment to ensure the highest level of precision in the optical aspheric domain. The use of cutting-edge correction polishing technology further enhances the lens surface, culminating in infrared aspheric lenses that boast an optical aspheric surface shape accuracy of ≤ 0.1 micron and a surface roughness of Ra ≤ 0.01 micron. These germanium lens represent the pinnacle of optical engineering, designed to deliver unparalleled performance in demanding applications.

| Infrared germanium lens product parameter table | |||

| project | Indicator requirements | ||

| 1. Material | Single crystal germanium infrared material. | ||

| 2. Diameter | OD±0.025 or as per customer requirements | ||

| 3. Center thickness | T±0.01 or according to customer requirements | ||

| 4. Effective focal length | according to customers needs | ||

| 5. Working distance | according to customers needs | ||

| 6. Effective aperture | ED>80% aspheric area | ||

| 7. Coating | AR or DLC coating R<0.5% @λnm | ||

| 8. Surface shape | Ultra-high precision Rt≤0.1μm, high precision Rt≤0.5μm, precision Rt≤1μm | ||

| 9. Surface quality | 60-40, 40-20, 20-10 | ||

One-stop customized production: Solar Valley processes various infrared lenses with plano-convex, biconvex and convex-concave structures according to customer requirements. The lens shape can be circular, D-shaped, square, trapezoidal and other structures.

Material: Single crystal germanium infrared material, in the range of 2-12 μm, germanium is the most commonly used material for producing lenses and efficient infrared windows in imaging systems, and can serve as the substrate for lenses, windows and output coupling mirrors.

Lens properties: uniform light spot, clear projection, complete specifications, aerospace quality, used in night vision goggles, medical endoscopes, laser processing, infrared thermal imaging cameras, temperature recorders, infrared fundus cameras, satellite infrared telescopes, etc.

Product indicator description:

1. Maximum dimensions of circular infrared aspheric lens: OD≤φ150mm

2. Maximum dimensions of square infrared aspheric lens: L×W ≤100×100mm

3. Infrared aspherical lenses can reach the following accuracy levels according to customer requirements:

Ultra-high precision grade: surface error <0.1μm, surface roughness <0.01μm

High precision grade: Surface error <0.5μm, surface roughness <0.05μm Precision grade: Surface error <1μm, surface roughness <0.1μm

Similar product of GaAs lens is also provided for you to explore.

Surface defect grade: 60-40, 40-20, 20-10. Produced according to customer requirements.

Coating: Coating according to customer requirements.

Germanium lenses, crafted from polished germanium, are known for their ruggedness and resistance to corrosion, making them ideal for harsh environments and applications with constant exposure to the elements. These germanium glass lenses boast the highest refractive index among readily available IR transmitters and exhibit minimal chromatic aberration due to low dispersion, making them perfect for infrared (FLIR and FTIR) field applications, thermal imaging systems, and precision analytic instruments used in harsh conditions. The unique hardness of germanium, with a Knoop hardness of 780, contributes to its durability, although its high density (5.33 g/cm3) requires consideration in weight-sensitive designs. However, germanium is subject to thermal runaway, where transmission decreases as temperature increases, rendering the lens opaque; thus, it should be used at temperatures below 100°C. Germanium offers optimal transmission (over 45%) in the 2-12 μm band, which can be enhanced to about 95% with anti-reflective coatings, making it highly effective for mid-infrared light applications. At Solar Vally, we offer a wide range of germanium lenses, including germanium IR lens, germanium thermal lenses, and germanium lenses for thermal cameras. For those interested in germanium lens prices, we provide competitive options across our extensive product range.

| Types | Products |

| A. Optical Lenses & Components | Germanium Lens Price |

| Cemented Achromatic Doublet | |

| Magnesium Fluoride Lens | |

| Laser Lens Factory | |

| Optical Glass Prism Cube | |

| Dichroic Mirror Price | |

| UV Dome | |

| Corner Cube China | |

| B. Optical Subassemblies (TOSA/ROSA/BOSA) | Transmitter Optical Sub Assembly (TOSA) |

| Receiver Optical Sub Assembly (ROSA) | |

| Bidirectional Optical Subassembly (BOSA) | |

| C. Quartz/Glass Products | Quartz Rods for Sale |

| Quartz Capillary Tube | |

| Quartz Capillaries | |

| Thin Wall Glass Tubing |