Call Us

86-755-82924037

Call Us

86-755-82924037

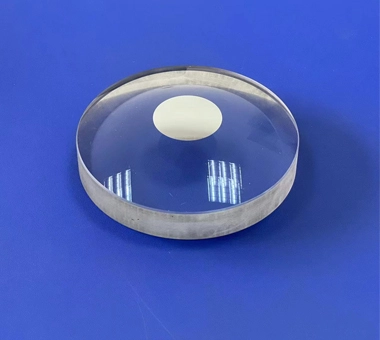

Molded glass aspherical lenses use ultra-high-precision molds to perform high-temperature molding on glass glass materials under the protection of inert gas at set high temperatures and pressures to produce glass aspherical lenses with high-precision contour accuracy and surface quality. . The advantages of the lens are low production cost, high precision, and suitable for mass production.

| Molded aspheric lens product parameter table | |||

| Project | Indicator requirements | ||

| 1.Material | Using high performance low temperature molded optical glass | ||

| 2. Diameter | OD≤3mm, OD≤30mm, OD≤100mm | ||

| 3. Center thickness | T≤2mm, T≤10mm, T≤50mm | ||

| 4. Effective focal length | According to drawing requirements | ||

| 5. Working distance | According to drawing requirements | ||

| 6. Design wavelength | 430~633nm, 630~780nm, 1550~1620nm | ||

| 7. Numerical aperture | According to drawing requirements | ||

| 8.Coating | AR antireflection coating R<0.2% @λnm | ||

| 9. Eccentricity | According to drawing requirements | ||

| 10. Effective aperture | ED>80% aspheric area | ||

| 11. Surface shape | Ultra-high precision Rt≤0.1μm, high precision Rt≤0.5μm, precision Rt≤1μm | ||

| 12.Surface quality | 60-40, 40-20, 20-10 according to drawing requirements | ||

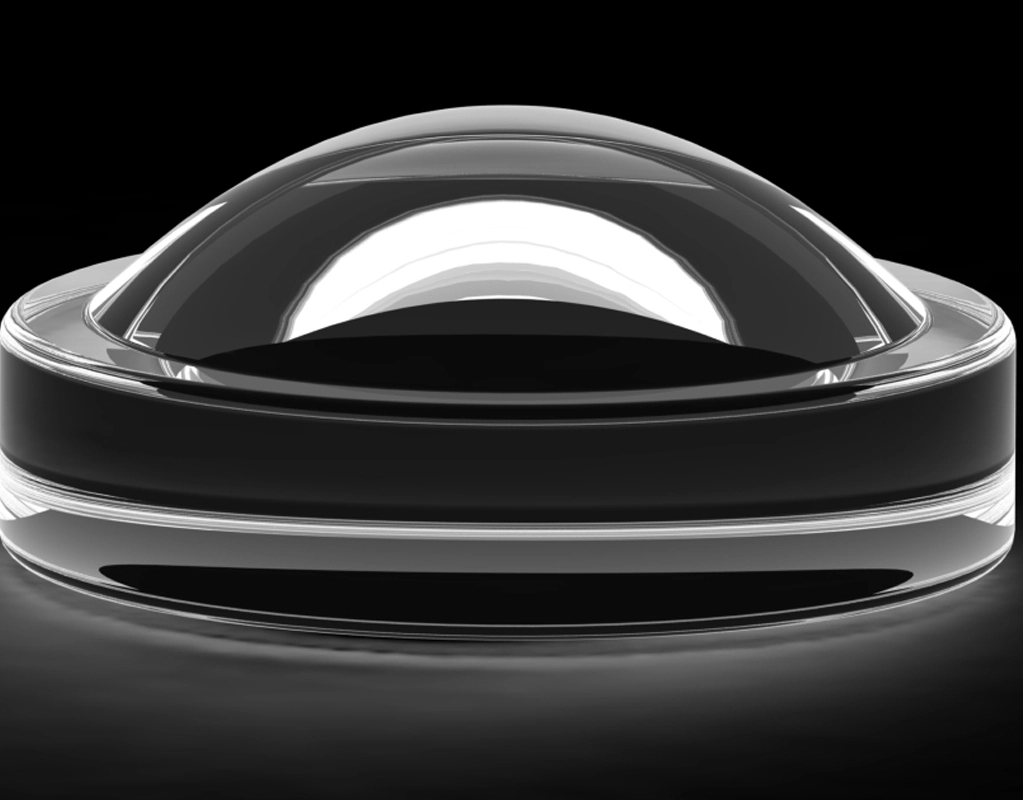

One-stop design and customized production: Solar Valley designs and high-temperature molds processes various plano-convex, biconvex, and convex-concave structure aspheric lenses according to customer requirements, for more custom aspherical lenses, contact Solar Valley.

Material: Solar Valley's molded lens materials are selected according to customer requirements, including low-temperature molded materials glass glass produced in Japan, China, and the United States.

Mold: Solar Valley produces ultra-high-precision aspherical compression molding molds with various structures according to customer requirements. The materials include tungsten carbide, ceramics, etc.

Lens properties: uniform light spot, clear projection, complete specifications, aerospace quality

Product indicator description:

a. Maximum dimensions of circular aspheric molded lenses:

Small diameter molded lens diameter ≤φ3mm Medium diameter molded lens diameter: ≤φ30mm Large diameter molded lens diameter: ≤φ100mm

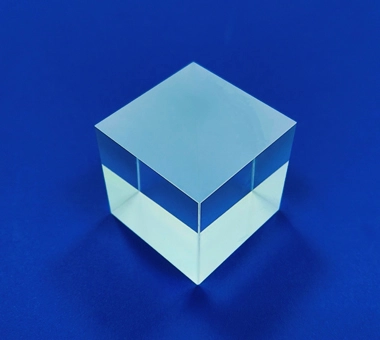

b. Maximum dimensions of square aspheric molded lenses: Dimensions of small molded lenses: ≤30×30mm Dimensions of large molded lenses: ≤70×70mm

c. Aspherical molded lenses can reach the following accuracy levels according to customer requirements:

Ultra-high precision grade: surface error <0.1μm, surface roughness <0.01μm

High precision grade: Surface error <0.5μm, surface roughness <0.05μm Precision grade: Surface error <1μm, surface roughness <0.1μm

d. Surface defect grade: 10-5, 20-10, 40-20, 60-40, produced according to customer requirements.

e. Coating: Coating according to customer requirements.

11