Call Us

86-755-82924037

Call Us

86-755-82924037

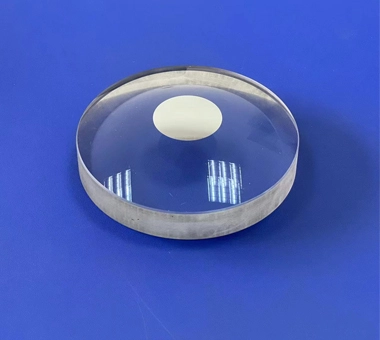

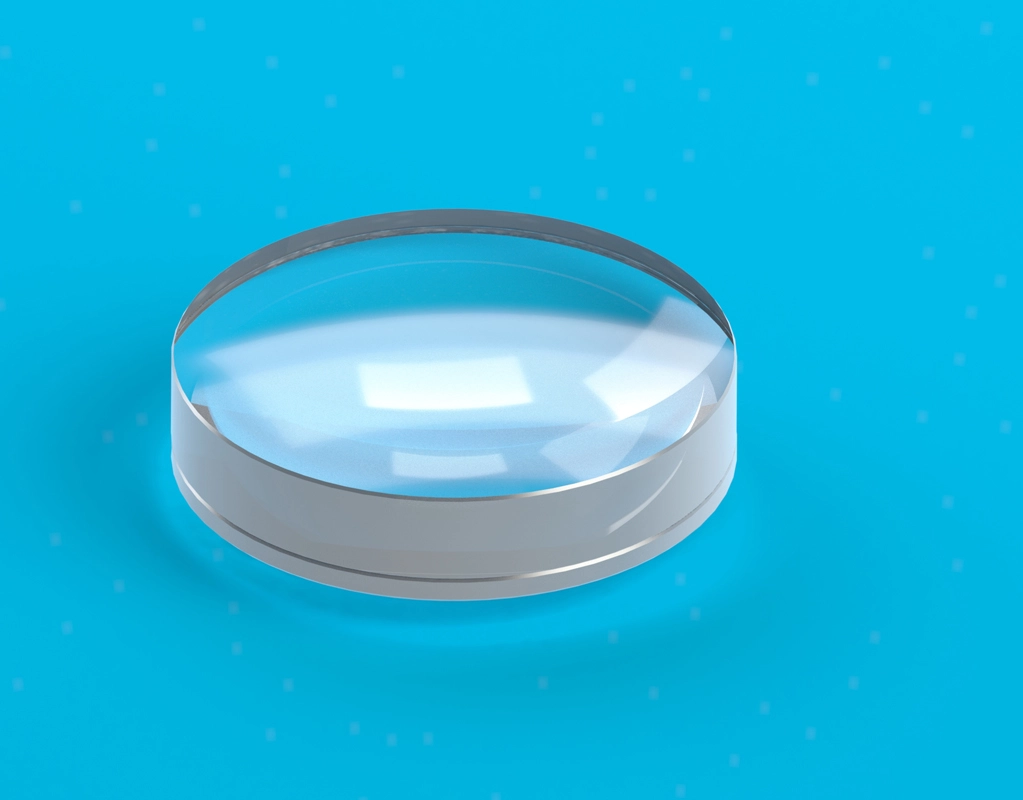

Achromatic doublets are suitable for eliminating chromatic aberration and reducing spherical aberration on the image plane. Typically by gluing two elements together or mounting both elements in a housing, these achromatic doublet lens produce a smaller spot size than comparable single-line lenses. Suitable for high-power laser systems, measurement, and imaging applications such as projection, photography, fluorescence microscopy, image relay, inspection, spectroscopy, and more. The single lens in the cemented achromatic doublet is processed through milling, fine grinding, grinding and polishing processes. Our negative achromatic lens can achieve optical surface shape accuracy ≤ 0.1 micron and surface roughness Ra ≤ 0.01 micron. The two lenses are glued together as a double lens, and a centering device with a UV photosensitive adhesive curing device is used to conduct precision gluing and eccentricity testing to produce an achromatic doublet lens.

| Achromatic doublet lens product parameter table | |||

| project | Indicator requirements | ||

| 1.Material | Use various high and low refractive index optical glasses and optical quartz | ||

| 2.Outer diameter | Round OD≤300mm, square L×W≤210×210mm ±0.05mm | ||

| 3.Thickness | T≤100mm±0.02 according to customer requirements | ||

| 4. Effective focal length | according to customers needs | ||

| 5. Working distance | according to customers needs | ||

| 6. Design wavelength | according to customers needs | ||

| 8.Coating | AR anti-reflection coating R<0.5% @λnm according to customer requirements | ||

| 9. Eccentricity | according to customers needs | ||

| 10. Effective aperture | ED>90% aspheric area | ||

| 11. Surface shape | Ultra-high precision Rt≤0.1μm, high precision Rt≤0.5μm, precision Rt≤1μm | ||

| 12.Surface quality | 60-40, 40-20, 20-10, 10-5 | ||

One-stop customized production: Solar Valley processes various round and square achromatic doublet lenses according to customer requirements, such as positive achromatic lenses, negative achromatic lenses, aspheric achromatic lenses, more achromatic lenses etc. wait.

Cemented Achromatic Doublet Material: Use various high and low refractive index optical glass and quartz substrates.

Achromatic doublet lens properties: Tianyanggu strictly matches the diameter and center thickness to ensure adhesive thickness and precise center thickness control to meet high precision requirements. Tianyang Valley uses UV curing/gluing technology on different glass materials to dynamically adjust the optical center of the two parts during the gluing process, eliminating the overall optical center eccentricity after gluing. For high refractive index optical materials, use high refractive index UV photosensitive glue to precisely control the center thickness tolerance of the glued parts, which can be used for optical designs that are very sensitive to air separation.

Explanation of product size indicators:

Maximum outer dimension of achromatic doublet lens: OD≤φ300mm

Maximum outer dimension of square achromatic doublet lens: L×W≤210×210mm

Center thickness of achromatic doublet lens T≤100mm

Achromatic doublet lens

The following accuracy levels can be achieved according to customer requirements:

Ultra-high precision level: surface error <0.1μm, surface roughness <0.01μm

High precision level: surface error <0.5μm, surface roughness <0.05μm

Precision level: surface error <0.05μm 1μm, surface roughness <0.1μm

Achromatic Doublet Surface defect grade: 60-40, 40-20, 20-10, 10-5 Produced according to customer requirements.

6. Achromatic Doublet Coating: Coating according to customer requirements.

The choice between a cemented and air-spaced achromatic doublet lens primarily depends on the specific requirements of your optical system.

| Cemented Achromatic Doublet Lens | Air-Spaced Achromatic Doublet Lens | |

| Ideal for | Applications where compact size and high stability are crucial. Systems operating in stable environmental conditions. Cost-effective solutions. | Applications demanding high optical performance. Systems operating in varying environmental conditions. Systems requiring a wide spectral range. |

| Advantages | Compact design High mechanical stability Generally lower cost | Greater design flexibility for aberration correction Less sensitive to temperature changes Wider range of glass material options |

| Disadvantages | Sensitive to temperature changes Limited glass material options | Larger size and weight Higher cost |

Optical Performance: If the highest possible image quality is required, an air-spaced doublet often provides better performance due to its greater design flexibility.

Environmental Conditions: If the lens will be exposed to varying temperatures or pressures, an air-spaced doublet is generally more suitable due to its higher stability.

Cost: Cemented doublets are typically less expensive to manufacture.

Size and Weight: If space and weight are constraints, a cemented doublet is the preferred choice.

Spectral Range: If the system operates in a wide spectral range, an air-spaced doublet might be necessary to achieve optimal performance.

carefully evaluate the specific requirements of your optical system to determine whether a cemented or air-spaced achromatic doublet is the best choice. Often, a combination of these lens types may be used in complex optical systems to achieve optimal performance.