Call Us

86-755-82924037

Call Us

86-755-82924037

Shenzhen Solar Valley boasts 24 years of expertise in high-precision processing and holds over twenty core technology patents.

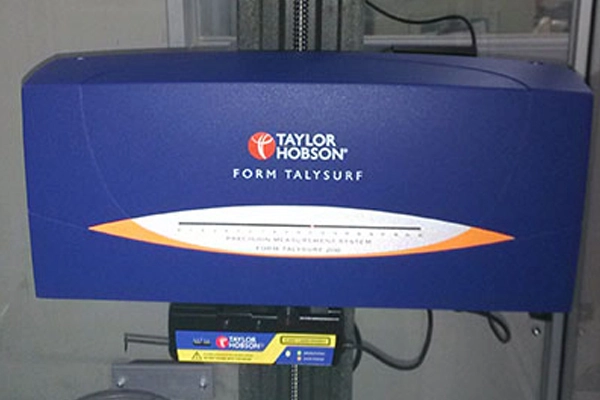

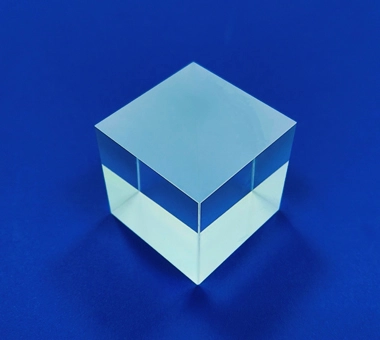

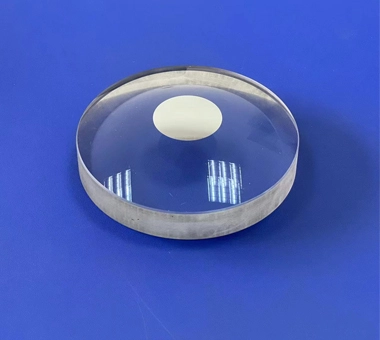

Specializing in the research and development, as well as processing, of non-metallic materials such as quartz, glass, and ceramics, Solar Valley optical lens manufacturer has accumulated extensive experience in both hot and cold processing. Equipped with ultra-high precision production facilities with an accuracy of ±0.1 micrometers, including single-point diamond turning machines, ultra-high precision CNC machining centers, array laser measurement devices, and high-magnification microscopes, the company stands at the forefront of technology.

Through independent research and development, a variety of processing tools and fixtures have been created, enabling the realization of a complete set of techniques such as grooving, cutting, drilling, curve forming, taper hole shaping, end face grinding, surface polishing, ultra-high precision freeform surface processing, and mirror grinding.